What is Acrylic foam tape?

3M 9448AB Tissue Double-Sided Tape

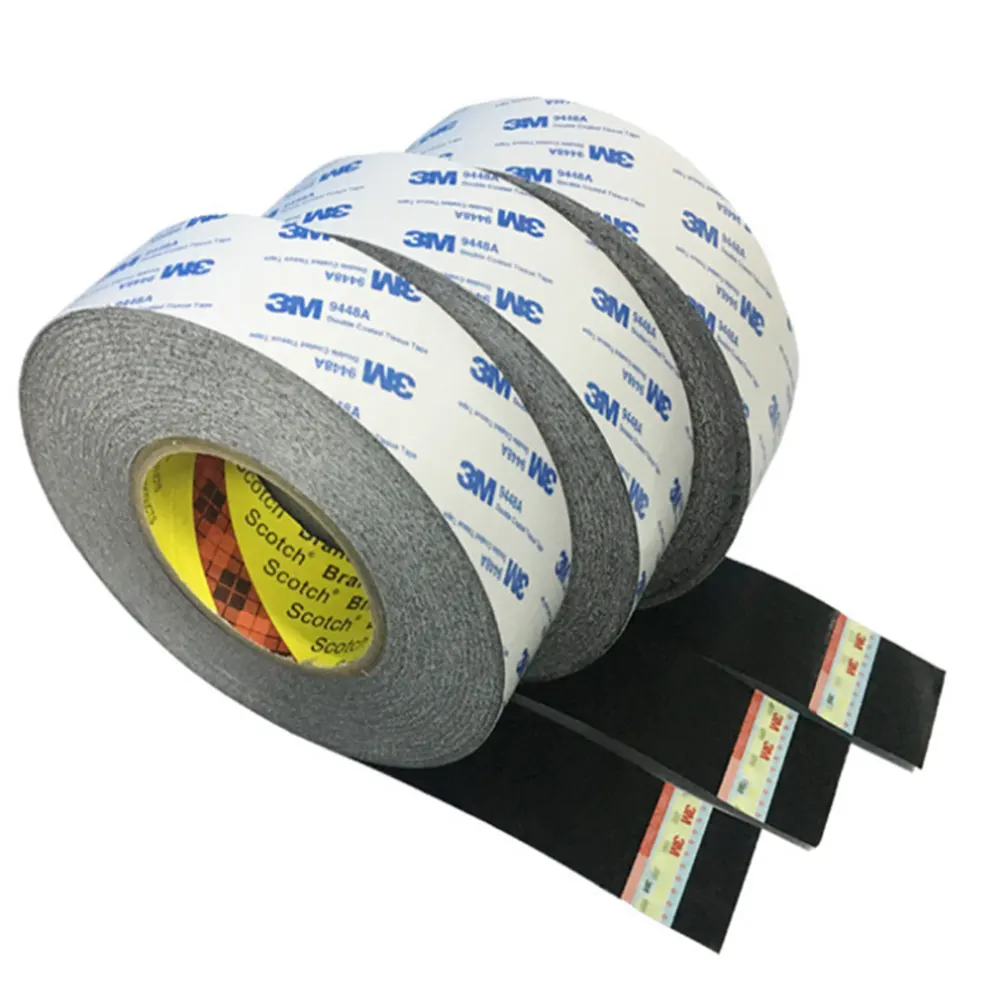

3M 9448A Tissue Double-Sided Tape

3M 9080HL Tissue Double-Sided Tape

3M 9080A Tissue Double-Sided Tape

3M 9077 Tissue Double-Sided Tape

3M 9075 Tissue double-sided tape

Golf double sided tape masking tape

Acrylic foam tape (AFT) is a relatively new industrial adhesive product that has gained in popularity over the past few years.

It is a double-sided tape made with a foam carrier material and an acrylic adhesive. The foam material provides a cushioning effect and allows for a greater degree of flexibility while maintaining optimal bond strength.

Acrylic foam tape is a popular alternative to traditional mechanical fasteners because of its numerous benefits. One of the primary advantages of AFT is its ability to bond dissimilar materials, such as metal, plastic, and glass. It also offers excellent resistance to UV, weather, and chemical degradation. Additionally, Acrylic foam tape has high peel strength, shear strength, and adhesive strength, making it an ideal choice for industrial applications that require a strong and reliable bond.

Properties of Acrylic foam tape?

Acrylic foam tape are available in a diverse array of thicknesses, adhesives, carriers, sizes, and cell structures, allowing them to be tailored for numerous applications and end uses. Each type of foam tape offers specific characteristics and benefits that make it well-suited for particular tasks.

Because Acrylic foam tape is so flexible, it may be used to fill gaps and conform to link unusual surfaces.

Acrylic foam tape can often tolerate temperatures between -40°F and 300°F (-40°C to 200°C).

Offers strong bonding to account for various thermal expansions.

Acrylic foam tape has a high adhesive strength for various temperature expansions and is resistant to moisture, ultraviolet light from the sun, and solvents.

Excellent shock absorption protection and good resistance to compression deformation are provided by this seal, which keeps out dust and moisture or prevents outgassing.

Environmentally friendly, free of toxic ingredients, and flame resistant.

Excellent wettability, ease of die-cutting, suitability for bonding and fixing of varied sizes, and ability to complete watertight sealing are all surface features. Other features include high adhesion, good weather resistance, and resistance to acid and alkali.

Acrylic Adhesive: The most typical adhesive for foam glue is an acrylic adhesive. Acrylic foam tape is ideal for indoor and outdoor applications because of its strength, high-temperature tolerance, and excellent UV resistance.

Rubber Adhesive: High viscosity and water resistance are two qualities for which this adhesive is known. Both smooth and rough surfaces can be used with it.

Silicone Adhesive: This adhesive is renowned for being flexible and heat resistant. Both indoor and outdoor use are appropriate for it.

Acrylic foam tape comes in different types, depending on the application. High-performance acrylic foam tape is designed for projects that require extreme bonding abilities, while standard acrylic foam tape is ideal for everyday bonding needs. Other types of acrylic foam tape include removable and repositionable acrylic foam tape, which allows for easy removal and repositioning without leaving any residue or damage.

There are numerous applications for acrylic foam tape in various industries, including automotive, electronics, construction, and signage. In the automotive industry, acrylic foam tape is used for exterior applications such as attaching exterior trims, badges, and emblems as well as interior applications like bonding interior trim panels and headliners. Acrylic foam tape is also used extensively in the construction industry to bond cladding panels, building signage, and windows.

Over the years, Acrylic foam tape has gained significant market acceptance because of its unique features and benefits. It is known for its reliable and durable bond, weather and temperature resistance, and versatility. Acrylic foam tape has become an essential product in various industries and is a viable alternative to traditional mechanical fasteners. By understanding its applications, types, and benefits, businesses and industrial applications can easily make informed decisions when choosing an acrylic foam tape product.

Applications of Acrylic foam tape?

Many enterprises and sectors can benefit from using foam tape. Here are a few situations where foam tape may be useful and necessary:

Medical Industry

Acrylic foam tape enhance infectious disease containment (IDC) equipment, which is especially beneficial in the medical field. They can be used to pad, seal, and insulate items such as splash guards and face masks. It is recommended that personal protective equipment (PPE) be lined with foam tape to ensure a proper seal and prevent contamination from bodily fluids and infectious agents.

Vehicle Industry

Acrylic foam tape with dual sides is ideal for securely fastening body edges and curves. It adheres strongly to various surfaces, including paint and external car parts. Because the body and external components expand and contract differently due to thermal changes, foam tape is effective in distributing stress. It also plays a significant role in noise reduction and providing watertight sealing for external trims.

Solar Industry

In the solar industry, Acrylic foam tape are used to bond components such as module back beams and concentrators that must endure harsh conditions. The quick-bonding capability of foam tape allows for fast and reliable assembly without compromising quality or requiring extensive curing time.

Gasketing

Foam tape is commonly utilized as gasketing tape. Adhesive-coated Acrylic foam tape act as compressible sealants to close gaps between machine parts or around pipe joints, preventing gas, fluid, air, or sound from escaping. Applications include sealing garage doors, shed doors, and electrical enclosures. Acrylic foam tape can serve as an alternative to rubber foams, pumpable sealants, and caulks.

Weatherstripping Uses

Foam tape is often used for weatherstripping applications. It is typically applied along doors and windows to keep cold air out during the winter and hot air out during the summer. Foam tape effectively fills gaps where seals around windows or doors are inadequate, providing a reliable, long-lasting, and cost-effective alternative to replacements.

Appliances

Foam tape simplifies the process of fixing translucent or transparent decorative panels on home appliances. Its invisible bonding ensures a clean appearance, absorbs vibrations to minimize noise, and provides strong adhesion to surfaces with low surface energy, such as plastics. Vinyl foam tape is also versatile for sealing HVAC systems and preventing drafts in homes due to its water resistance.

Building Renovation

Foam tape can be used for repairs, adhesion, or insulation in homes or commercial buildings by professional handymen or women. It is also suitable for use by office workers, restaurant managers, and other personnel for various repair tasks.

Wind Energy

In the wind energy sector, Acrylic foam tape are used to join exterior components of wind blades, such as deflectors and serrated trailing edges. Foam adhesives help reduce assembly times and enhance blade processing in factories. They provide excellent stress dispersion and weather resistance for both outdoor and indoor applications.

Electronic Products

Double-sided foam tape is ideal for bonding touch screens, windows, and backplanes on electronic devices like smartphones and tablets. With the increasing popularity of narrow bezel designs, foam tape ensures that cover glass remains securely attached, protecting against impact forces from drops and collisions. Urethane foam tape also helps reduce sound in electronic devices, such as keyboards and printers.

Transportation

Foam tape is effective for assembling parts in the ceilings, walls, and floors of trains, high-speed rail, and airplanes. It enables secure and compliant fastening according to established standards.

Architecture

Indoor Wall Covering: Changing a room’s aesthetics quickly and affordably without employing a pricey designer or contractor is possible with foam tape. One can change every surface into something new with just one piece. In addition, panels can be swiftly and neatly installed using tape without causing material damage or waiting for the adhesive to cure.

Furniture Decorative Panel Fixing: To provide cabinets or closets with an attractive appearance, decorative panels made of glass, wood, and glazing are often found there. The foam tape supports a certain amount of the panel’s weight, which can be supported by the foam tape, which also completes a solid and long-lasting fixation between various materials.

Glass Partition Wall Bonding: Aluminum or glass profiles can be combined using double-sided foam tape. This material’s transparency produces an undetectable bonding effect for partition walls that is ideal for filling in any gaps in the project.

Curtain Wall Bonding: Decorative walls can be covered to create striking architectural façades. Because they produce a cleaner and more aesthetically-pleasing look while meeting the strict requirements of external weather resistance, Acrylic foam tape are a great substitute for conventional mechanical fixing methods.

Comments on “What is Acrylic foam tape?Types and Application?”